The world of manufacturing has undergone a significant transformation over the past few decades – with the rise of automation. Traditional manufacturing practices, which once relied heavily on manual labor, have given way to more efficient and cost-effective automated processes. However, with this change comes a significant impact on traditional manufacturing career paths. As machines and robots take over certain tasks, the necessary skills and qualifications for employees are also evolving. In this article, we will explore the impact of automation on traditional manufacturing career paths and how individuals can adapt to these changes.

The Rise of Automation in Manufacturing

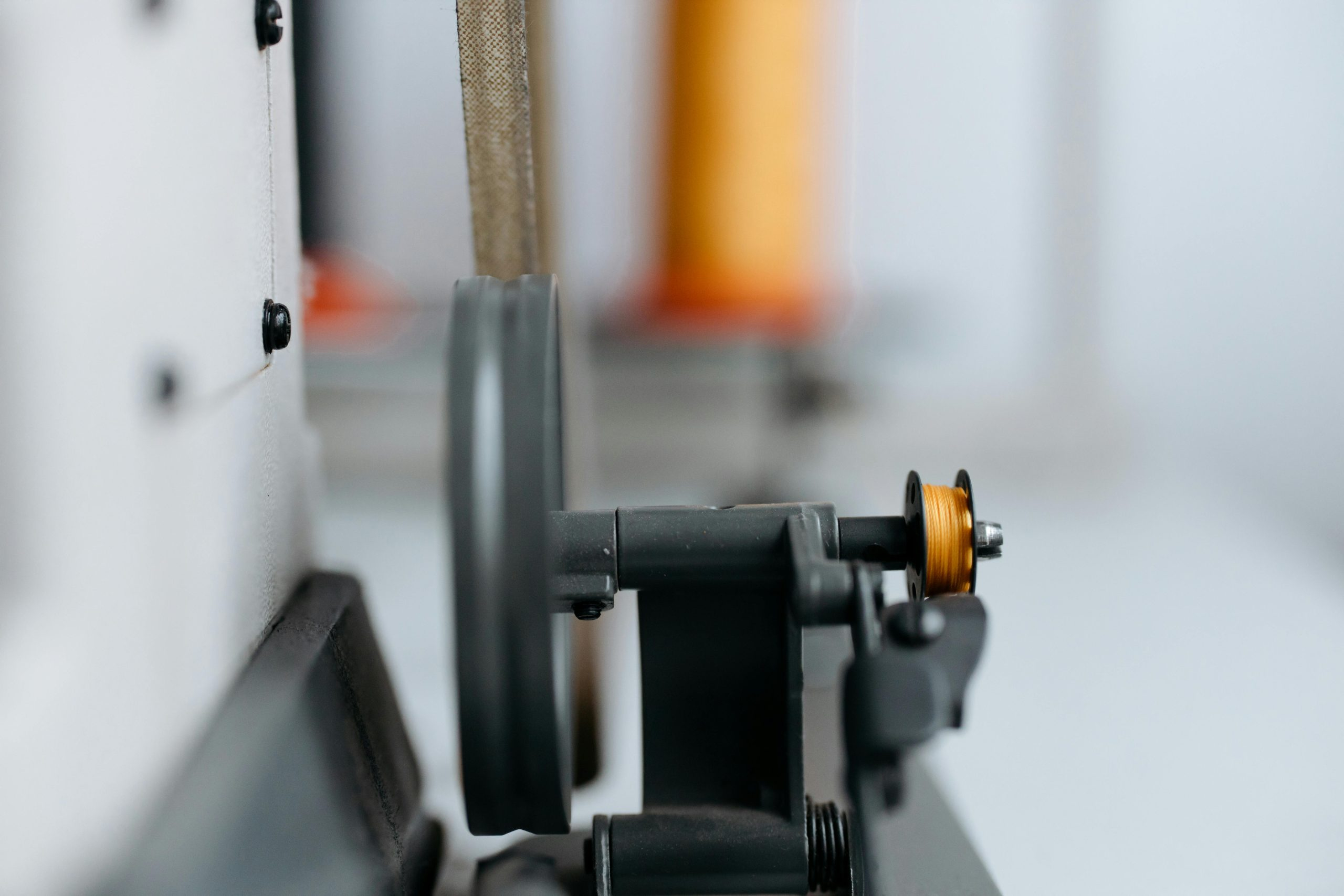

Before delving into the impact of automation on traditional manufacturing career paths, it is essential to understand the concept of automation and its growth in the industry. Automation involves using machinery and technology to perform repetitive or monotonous tasks that were once done manually by workers. This shift towards automation has been driven by the need to increase production efficiency, reduce costs, and improve product quality.

According to a recent report by the World Economic Forum, automation is expected to displace around 75 million jobs globally by 2022. While this may seem alarming, it is worth noting that automation also creates new job opportunities, particularly in the manufacturing sector. Positions such as robotics engineers, process automation specialists, and data scientists are in high demand, highlighting the need for individuals to upskill and adapt to the changing landscape.

The Impact on Traditional Manufacturing Career Paths

Shift in Job Responsibilities

One of the most significant impacts of automation on traditional manufacturing career paths is the shift in job responsibilities. As machines and robots take over certain tasks, workers will need to adapt to new roles that involve managing and overseeing automated processes. This might include programming and maintenance of the machines, as well as data analysis and process optimization. The traditional hands-on, manual tasks will be replaced by more technical and analytical responsibilities, requiring a different skill set.

Increased Demand for Technical Skills

With automation becoming a standard practice in manufacturing, there is also a growing demand for individuals with technical skills. Employers are now seeking individuals who have a solid understanding of robotics, automation, and data analysis to manage and optimize the automated processes. As traditional manufacturing career paths evolve, workers will need to upskill and acquire new technical skills to remain relevant in the industry. This may involve enrolling in specialized courses or attending training programs to stay updated with the latest advancements in automation technology.

Higher Paying Jobs

While automation may result in the displacement of certain manufacturing jobs, it also opens up new opportunities for individuals. The technical nature of these roles often commands a higher salary, making them a more attractive career path for those with the necessary skills. This is especially true for positions that require a combination of technical expertise and experience in the manufacturing industry. As automation continues to grow, the demand for skilled workers will increase, creating more opportunities for individuals to advance their careers in this field.

Reduced Physical Demands

One of the most significant benefits of automation for workers is the reduced physical demands of the job. Traditional manufacturing careers often involve physically strenuous tasks, which can be challenging for some individuals, particularly as they get older. With automation, many of these tasks will be taken over by machines, resulting in a safer and healthier work environment. This can also lead to increased job satisfaction, as workers can focus on more intellectually stimulating tasks rather than repetitive physical labor.

Adapting to the Changing Landscape

As automation continues to impact traditional manufacturing career paths, individuals need to adapt and acquire new skills to remain relevant in the industry. This may involve pursuing higher education or attending training programs to learn about the latest automation technologies. Additionally, individuals can also seek opportunities to work alongside the machines and learn how to manage and maintain them effectively.

Another way to adapt to the changing landscape is to stay updated with the latest industry trends and advancements. This can be achieved by networking with professionals in the field and attending conferences or workshops related to automation in manufacturing. Additionally, individuals can also consider internships or apprenticeships to gain hands-on experience and learn from experts in the field.

Conclusion

The increasing use of automation in traditional manufacturing has both positive and negative impacts on career paths in the industry. While it may lead to the displacement of certain jobs, it also creates new opportunities for individuals with the necessary technical skills. As automation becomes a standard practice, it is essential for individuals to remain adaptable and continually upskill to stay relevant in the industry. By staying updated with the latest advancements and acquiring new skills, individuals can thrive in this ever-changing landscape.